Understanding IMSMA Information Model

Data Types

Core Data

In the IMSMANG information model, items are the containers for mine action core data. An item is an area, activity or event that a mine action programme records information about and stores in IMSMANG. There are six categories of items, which are described in the table below. Each category can be characterized by a type that reflects whether the item is designed to track process or activity information or the object or product of an activity.

| Item | Description | Type |

|---|---|---|

| Hazard | Information about an area affected by a hazard | Object/Product |

| Hazard reduction activity | Information about an activity to survey, clear, or reduce the threat of a hazard | Process/Activity |

| Accident | Information about an event involving a hazard | Object/Product |

| Victim | Information about a person injured or affected by a hazard | Object/Product |

| Mine Risk Education (MRE) activity | Information about an activity designed to inform or educate people about hazards | Object/Product |

| Quality Management (QM) activity | Information about an activity to control and monitor the clearance and/or reduction of hazards or hazard reduction activities | Object/Product |

Items are entered into IMSMANG by means of a field report. Typically, each category of items has its own field report template for recording information specific to that category. When entered into IMSMANG, all field report items must be assigned to a location, which is tied to the country’s gazetteer, or political or administrative structure. The items can then be traced back to the country structure so that users can easily report data such as the number and size of hazards within a particular province.

Part of defining and documenting an information model includes defining the useful information attributes for each IMSMANG item. IMSMANG comes with more than 1,000 data elements already defined as well as the capability to create additional custom-defined fields (CDFs). This makes it important to critically assess which data elements are useful to a programme for decision-making, analysis and reporting and to focus on those while ignoring data elements that don’t provide additional value. Limiting information to only that which is useful to the programme provides long-term benefits including reducing the data collection and data entry burden and improving system performance. And, while many data elements may be collected for each IMSMANG item, some elements may be more important for analysis than others. For example, whether a victim has been injured or killed may be more important for analysis than the victim’s nationality.

| Item | Subcategory Examples |

|---|---|

| Hazard |

|

| Hazard reduction activity |

|

| Accident |

|

| Victim |

|

| Mine Risk Education (MRE) activity |

|

| Quality Management (QM) activity |

|

Each of the six categories of items can be divided into subcategories or types so users can collect information for each subcategory. For example, users can specify different types of hazards such as dangerous areas, confirmed hazardous areas (CHAs), minefields and battle areas and manage each kind of hazard differently. Using subcategories, information managers can:

- create separate workflows for each type of hazard

- create and manage separate data entry forms

- differentiate between item categories on the map

Additionally, information managers can customise the subcategories so that unused subcategories can be removed and other subcategories added. The same is true for all top-level items within IMSMANG, which lets information managers specify their exact information model, including the relationships among item categories, and adjust the model as their needs change over time. To accurately map the information model for a programme, it’s helpful to evaluate the available item subcategories and determine if changes to the information model in IMSMANG are required. While these values can be customized after system setup, understanding the types of information for each item is critical to implementing an effective workflow in IMSMANG. Table 5 shows examples of the possible subcategories of IMSMANG items.

Document the following decisions about items:

- data elements to be collected and managed in IMSMANG

- data elements that are not predefined in IMSMANG and should be created as CDFs

- particularly important, or key, data elements for the programme

- relevant subcategories for each item

- status values for each item

Below is an example of a fully-documented hazard.

Example of Documented Hazard

Auxiliary Data

In addition to defining the required information for IMSMANG items, it is important to define the relevant information to be collected about auxiliary data. This includes defining and documenting the Country Structure, Explosive Ordnance, Organisation and Place, such as military bases, hospitals and cultural sites; any additional CDFs that should be created; and any subcategories for each of the auxiliary data types.

Document the following decisions about auxiliary data:

- data elements to be collected and managed in IMSMANG

- data elements that are not already configured in IMSMANG and can be created as CDFs

- relevant subcategories for each data type

Below is an example of a fully-documented place.

Understanding IMSMA Information Model - Example of Documented Auxiliary Data

Field Reports and Current Views

A field report is a data entry form used to record and store information about an item.

A current view is a summary of all the information collected about an item on field reports.

Reconciliation is the process of assigning the information in a field report to an existing item or creating a new item/current view.

All mine action information is entered into IMSMANG via a field report, a data entry form used to collect information about an item. When a field report is completed, it is either reconciled to an existing item (that is, it is determined to be information about an item that already exists in IMSMANG) or it is reconciled as new (that is, it is determined to be information about an item that does not already exist in IMSMANG).

With this approach, users can collect and store multiple field reports about the same item over time so that the entire history of the item is preserved in the system. The approach also provides a complete audit trail of all changes made to any mine action information so that information managers can answer the question, "What did we know and when did we know it?"

IMSMANG also provides a constantly updated current view of the item which represents the sum of information about the item at any given time. As subsequent information is collected about a specific attribute of an item, IMSMANG updates the item’s current view on an attribute-by-attribute basis. For example, Field Report #1 collects some initial information about a hazard. It sets the priority to "Medium" and specifies that the hazard contains AP mines and is 25,000 sqm. Field Report #2 updates information about the hazard after a subsequent assessment. The report sets the priority to "High" and specifies the presence of AP and AT mines, but it does not change the size or the status of the hazard. Field Report #3 updates the hazard’s size and status after clearance operations are complete. The figure below shows how the hazard’s current view is updated after all three reports are entered into the system.

Example of Updating Current Views

Current view calculations are based on the date of the field report, so it is possible to enter data into the system out of chronological order (that is, to collect past information about an item) without disrupting the current view. For example, if a fourth field report were collected and dated between Field Report #1 and Field Report #2, it would have no effect on the current view as all information in the example was updated with Field Report #2 or later.

Mapping the Workflow

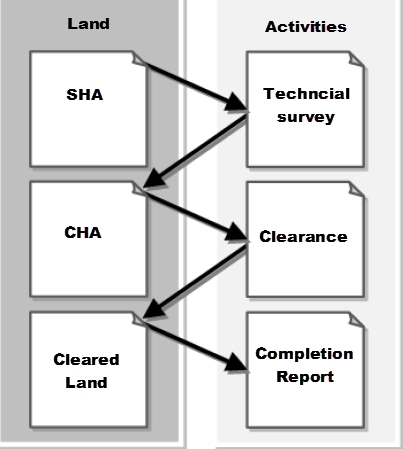

The first element of mapping the hazard reduction workflow is to build a map of the relationship between the objects and processes involved in the hazard reduction process. Starting with the first representation of the hazard, the workflow map should describe the processes done to the hazard and the output of the process. The workflow map should trace the entire process from hazard identification through clearance and release of the land according to the operational process in use in the programme. In the example below, a confirmed hazardous area (CHA) is linked to a technical survey that was conducted on the hazard. The survey resulted in a minefield on which a clearance was done, and the clearance resulted in a cleared hazard. Finally, a completion survey was logged to close the hazard.

Mapping the Workflow

This workflow map identifies the hazard reduction process that is used within the programme and can be mapped in IMSMANG to track the clearance of hazards. Because IMSMANG supports customisable workflows, it can be used to track different workflows for different objects. For example, a programme may have a separate abbreviated workflow for spot UXO tasks that involve only the identification of the UXO hazard (object) and a clearance of the hazard (process) without additional surveys or steps. This process should also be mapped for implementing in IMSMANG.

Business Rules Updating Structure

Status Changes

Along with a workflow map that describes the relationship between the various types of objects and processes in a workflow, the status changes or outputs from the process are critical in adequately mapping the hazard clearance process. IMSMANG uses the status value of items to track where the object or process is in its workflow. Objects and processes in IMSMANG can have different status values. For example, hazards can be defined as "Active", "Worked On," or "Closed," while hazard reduction activities that are more process-oriented can be "Planned," "Ongoing," "Completed," "Suspended," or "Aborted." Defining a set of status values for each item provides the capability to:

- manage workflows according to status

- search and report on items based on a particular status

- display items on the map with different symbols based on their status

Some IMSMANG items may have many status values. For example, process-oriented items such as hazard reductions and quality management likely have many status values, but hazards and other object- or output-oriented items typically have only the three status values listed above. Some items like victims and accidents may not need status values depending on how information is used. Defining the possible status values for each object in the workflow as outputs of the processes conducted on them provides a set of business rules for information management that govern how information should be entered and analysed.

Example Workflows with Status Changes

The following figures show how each programme can tailor the system to support a specific hazard clearance/reduction workflow process for each type of hazard, from a traditional process for minefield clearance with multiple steps including a technical survey, clearance and completion survey to a simplified process for UXO clearance that includes only a clearance. Each example involves a single hazard on which one or more hazard reduction activities are conducted. At each step, information about the hazard’s status and type is updated as a result of the hazard reduction process.

In the figure below, a CHA is created and its status is set to "Active." A technical survey process is then conducted on the hazard which results in changing the subcategory of the hazard from "CHA" to "Minefield" and defining the hazard’s perimeter. Next, a clearance process is conducted on the minefield that results in updating the status of the hazard to "Worked On." Finally, a completion survey is submitted that updates the status of the hazard to "Closed."

Example of a Traditional Workflow

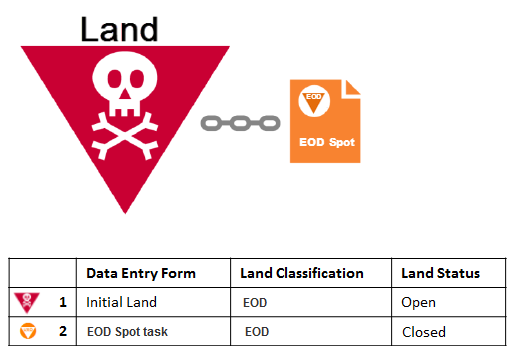

Simpler processes can be defined for other types of hazards. For example, a spot UXO task would likely not go through this complete workflow and instead start with a subcategory of "UXO" and a status of "Open." A clearance could then be conducted and the UXO spot status updated to "Closed," without requiring a completion survey.

Example of a Spot UXO Workflow

By documenting the entire process conducted on each type of hazard, including the changes in status and type that result from the hazard reduction activities, information managers create a complete map of the hazard/hazard reduction workflow that informs how linking and reconciliation decisions should be made and provide a guide to data entry personnel.

Progress Reporting Structure

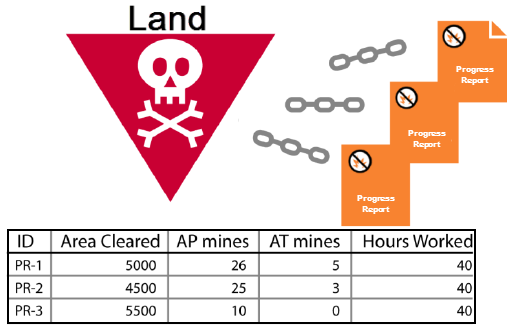

Once the hazard and hazard reduction relationships and workflow are defined and documented for each type of hazard, the next step is to define how progress data for the hazard clearance processes is collected. Traditionally, incremental progress data is collected using progress reports. These reports are typically linked to the overall clearance operation and are used to collect the incremental progress for a reporting period, usually, the number of mines/UXO cleared, area cleared and hours worked. In IMSMANG, each progress report is stored as a new hazard reduction activity and linked to the clearance. As a result, individual progress reports can be queried to determine how much progress was made during a given reporting period. In addition, aggregate progress information can be queried for each clearance (for example, the total mines that have been reported cleared for a given clearance operation).

An alternative approach to storing progress information is to collect incremental progress reports and reconcile them as updates to the clearance using the combine option during reconciliation. Using this method, progress reports do not create independent hazard reduction items; rather, their information is combined with, and added to, the clearance information collected to that point. This approach simplifies the reconciliation step for progress reports as well as provides a simple summary of clearance data on each hazard in the current view. It may, however, become slightly more complicated to determine progress during individual reporting periods. Information managers should assess which approach better meets the needs of their programs when selecting an approach to tracking progress.

In the example below, progress reports were collected for three separate reporting periods during a clearance operation. Collecting and linking information in this way makes it easy to determine that in Period 2 (PR-2), 4,500 sqm were cleared and 25 AP mines were found and that, overall, 15,000 sqm were cleared and 61 AP mines were found. A defined, standardized approach to collecting and storing progress information simplifies querying and reporting of statistical information and is a critical element to supporting operational mine action information management needs.

Progress Report Workflow